Home / Products / Electrolyzer / Sodium Hypochlorite Electrolyzer

Di Noer not only provides complete Sodium hypochlorite generation system, but also the core component of machine-----electrodes and cells(Sodium Hypochlorite Electrolyzer). The electrodes are made of pure Titanium, with ruthenium & iridium oxide coating which ensures over 5 years coating life, over 18 years for base material, reducing the electricity consumption and chlorine evolution potential.

Product Description

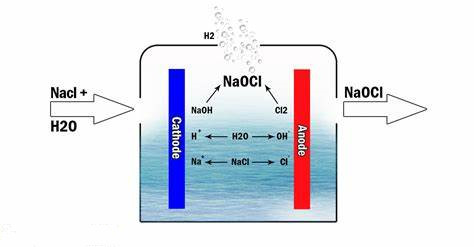

A direct current is passed through seawater or salt water, the electrolyzer generates chlorine (Cl2) on the anode surface and caustic soda (NaOH) on the cathode surface. The chlorine and caustic soda react to produce sodium hypochlorite (NaClO).

Sodium Hypochlorite Electrolyzer(electrodes or electrolysis cell) is designed for producing 8000ppm-10000ppm sodium hypochlorite through 2-5% brine, which is stable and safety running on-site.The electrolysis unit adopts a membrane-free electrolysis unit.

Moreover, custom service and various high performance anode products are provided by Di Noer, please feel free to contact us for a free quotation!

Technology Comparison

Part of the Specifications:(Other specifications can be customized)

available chlorine (g/h) | DC/A | DC/V | Capacitance pressure | Flow (L/h) | Brine concentration |

50g/h | DC/A≤60A±20% | DC/V≤5V | ≤0.2MPa | 7L/h----8L/h | 2-5% |

100g/h | DC/A≤125A±20% | DC/V≤5V | ≤0.2MPa | 20L/h----25L/h | 2-5% |

300g/h | DC/A≤84A±20% | DC/V≤20V±5% | ≤0.2MPa | 30L/h----35L/h | 2-5% |

500g/h | DC/A≤120A±20% | DC/V≤30V | ≤0.2MP | 75L/h----85L/h | 2-5% |

1000g/h | DC/A≤156A±20% | DC/V≤40V | ≤0.2MPa | 105L/h----110L/h | 2-5% |

2000g/h | DC/A≤185A±20% | DC/V≤50V | ≤0.2MPa | 135L/h----145L/h | 2-5% |

Constituent Part

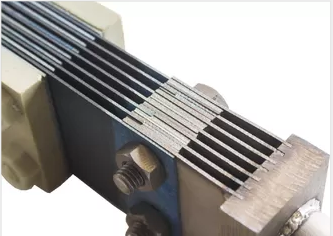

Electrode (electrolyzer)

1. Ensure lower power and salt consumption, high chlorine production and low running cost;

2. 2mm thickness pure titanium electrode – ensure long service life;

3. Small space occupation;

4. 2-3mm thickness pure titanium electrode, 25 times ruthenium iridium oxide coating;

5. High-frequency, stability and constant current power specialized for ship-leveled electrolytic power. Electric conversion efficiency: ≥92%.

Application

1. Sodium hypochlorite generator

2. electrolytic production of chlorine from brine

3. Electrolytic disinfection equipment

4. water treatment

Specifications

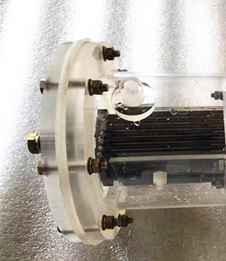

1. The tube type electrolytic cell is made of transparent UPVC pipe or PMMA, and has the advantages of corrosion resistance, high stability and long service life.

2. Titanium flange and titanium welding-prevent high voltage,ensure firm welding and high efficiency.

3. The titanium electrode, using patent technology of electrode structure,sharply low down the consumption of electricity and salt, the chlorine evolution potential<1.132V HIL, consumption of salt<3.5Kg/Kg.CL, 4.OKW/Kg.CL power consumption, much better performance than normal electrode.

4. The anode is covered by ruthenium, iridium oxide fine Nanometer coating,which is up to 20-25 layers ,ensure a very long service life (5 years warranty).