Home / Products / Lead Dioxide Titanium Electrode / Lead dioxide titanium electrode

Lead Dioxide Titanium Electrode, also known asTi/PbO2 anode, is a DSA anode( insoluble anode) which plating lead dioxide coating on titanium substrate. This anode has strong oxidizing property and corrosion resistant. It can be applied in many fields like Electroplating, Non-ferrous Metals Electrowinning, Electrochemical water treatment and Chlor-Alkali Industry.

Product Description

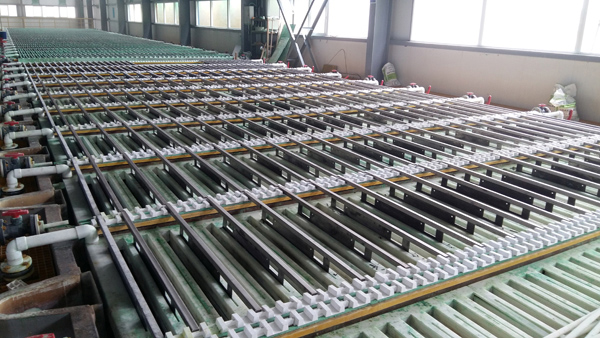

Made from industrial pure titanium substrate coated with precious metal lead dioxide, the lead dioxide titanium anode has perfect corrosion-resistance, high overpotential for the oxygen evolution reaction, big current density, adaptable for various oxygen evolution system conditions. The appearance of the lead titanium dioxide anode is black with shapes of tube, mesh and board etc.

As a professional titanium electrode supplier, Di Noer can also design and produce plenty of high performance MMO Auxiliary Anode for Cathodic Protection, MMO Coated Titanium Anodes and Platinum Plated Titanium Anode with best price. Welcome to consult for detailed information and custom service!

1. The cell voltage is lower than the lead-based anode: 0.05V-0.1V;

2. The weight of the electrode is relatively light and the operation is relatively convenient

3. Long service life, 1-2 times than that of lead-based alloy.

Technology Comparison

Technical parameter:

Base metal | TA1/TA2/Gr1,/Gr2 |

Coating | Lead dioxide |

Current density range | <3000A/M2 |

Thickness of coating | 1-10um |

Electrode shape | Net, tube, rod, plate.etc. |

Temperature range | <80℃ |

Fluoride ion content | <20mg/L |

Ph value | 1-12 |

Application

1. Electroplating: Nickel,chromium,zinc,copper,gold plating etc.

2. Non-ferrous Metals Electrowinning:Copper/Copper foil/Gold/Silver/Chromium/Cobalt/Manganese

3. Electrochemical water treatment: domestic sewage treatment, fading treatment of phenol-containing wastewater, oilfield wastewater, printing and dyeing wastewater, ammonia nitrogen wastewater, etc.

4. Chlor-Alkali Industry.

Specifications

1. TiO2 nano particles coating can bond well with the substrate,make it has higher anti-corrosion performance and long working life;

2. High current density and high production efficiency;

3. Various sizes and shape can be customized according to actual needs;

4. After the electrode loses its activity, the matrix can be repeated coating,save material cost.