Home / News / Applications of Platinum-plated Titanium Anodes

May. 30, 2022

Platinum is preferred for the outer surface of the anode because it is highly resistant to corrosion and ensures that current flows through most electrolyte media without causing it to form an insulating layer of its own. Because it does not corrode, it does not produce corrosion products and therefore has a very low consumption rate. DINOR will show you the benefits of titanium.

Titanium shows fairly good resistance to the marine environment (especially seawater). It does not react with concentrated (80%) solutions of metal chlorides. However, it is susceptible to higher concentrations of hydrofluoric acid (HF) and hot hydrochloric acid (HCl). Even hydrogen peroxide and hot nitric acid will corrode titanium. Oxidizing agents do not usually corrode titanium because it readily forms protective oxide coatings. However, non-oxidizing substances such as sulfuric acid (concentrations above 5%) and phosphoric acid (above 30%) will corrode titanium. From the point of view of hydrogen embrittlement, titanium is better as an anode material than tantalum.

The main applications of platinum-plated titanium anodes are in the field of metal surface treatment and cathodic protection of ferrous metals. In some of these applications, platinum titanium anodes successfully compete with cheaper graphite and lead electrodes. Process plants using platinum-plated titanium include electrolytic chlorination plants, breweries, paper mills and manufacturers of chemicals such as reagents, perchlorates and chlorates.

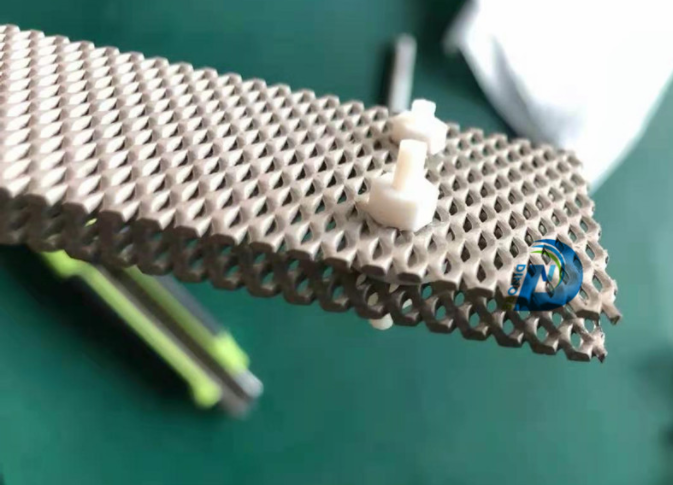

Platinum-plated titanium anodes are widely used in electrolytic processes. They have successfully replaced lead anodes in electroplating applications due to their low consumption, dimensional accuracy, ability to form precise deposit thicknesses on desired geometries, predictable plating chemicals and ease of maintenance. These anodes can be designed and formed into a variety of geometries depending on the part to be plated. Platinum on titanium anodes is a very preferred anode for electrodeposition of copper, chromium, platinum, nickel, palladium and gold.

Platinum plated titanium is mainly used as an anode material for cathodic protection of marine vessels, especially for corrosion protection of hulls and their components, including rudders, pump systems, rotating parts, propellers, pipelines, underwater components and structures, ballast tanks, dock system structures and cargo holds.

Platinum-plated titanium anodes are used in cathodic protection systems for underground storage tanks, pipelines, tank bottoms, cable sheaths and structures buried under corrosive soils. (Learn more about the effects of soil corrosion in the Soil Corrosion Profile.)

Platinum-plated titanium anodes and tantalum anodes are used in cathodic protection systems to protect pipelines, casing, pumping rods and above-ground storage tanks from corrosion.

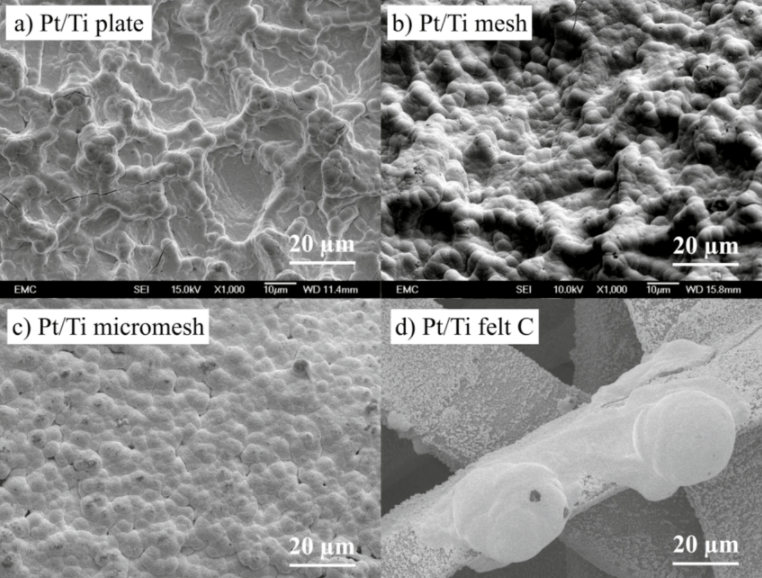

The manufacture of platinum-coated titanium anodes has been developed and improved over the past two decades. While electrodeposition techniques for coating platinum continue to be popular, the difficulty of achieving an adhesion coating on titanium has been overcome by pre-roughening the titanium surface and pre-coating the etched substrate with a very thin film of conductive primer.

For cathodic protection systems in power station condensers using a mixture of river water and seawater, the platinum consumption rate rises sharply due to the simultaneous production of oxygen and chlorine, and in brackish water, due to the presence of dissolved solids. Platinum rises to several tens of micrograms per ampere-hour.

In the case of nickel plating, the presence of brightening agents affects the platinum consumption rate, which is exacerbated by the sugar content in the brine feedstock in the steel vessel.

With the advantages of lower maintenance costs, improved deposition quality, and higher productivity and consistency, platinum-plated titanium anodes have successfully replaced lead anodes in hard chrome plating. They have become the preferred choice of corrosion engineers for applied current type cathodic protection of steel exposed to the marine environment. Newer applications are being developed to take advantage of the superior properties of platinized titanium. Please contact us today if you have any questions.