Home / News / Causes of Passivation of Ruthenium-iridium Titanium Anodes

Apr. 13, 2022

Titanium ruthenium iridium titanium anode consists of titanium substrate and ruthenium iridium titanium active coating, the role of electrochemical reaction is only the ruthenium iridium titanium active coating, if the coating and the substrate is not firmly enough combined, from the titanium plate substrate, off to a certain extent, titanium ruthenium iridium titanium anode will lose its role.

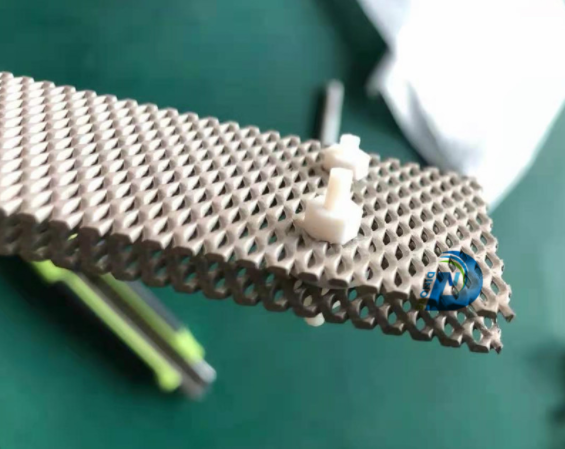

Platinized Titanium anode Mesh

Reduce the occurrence of oxygen, then the generation of oxide film can be slowed down. When the total current density of electrolysis increases, the increase in the rate of chlorine generation is much greater than the increase in the rate of oxygen generation, so the increase in current density is conducive to the reduction of oxygen content in chlorine. The titanium substrate is pre-oxidized to form an oxide film first, which increases the bonding of the ruthenium-iridium-titanium active coating with the titanium substrate and makes the coating firm, which prevents the shedding and dissolution of ruthenium, but also causes an increase in the ohmic drop of the ruthenium-iridium-titanium anode.

The active coating is composed of non-chemometric RuO2- and TiO2, which are oxygen-deficient oxides. The more such oxides, the more active centers there are and the better the activity of the ruthenium-iridium-titanium anode.

The electrical conductivity of the ruthenium-iridium titanium coated anode is the performance presented by the distorted n-type mixed crystal generated from the same crystalline RuO2 and TiO2 by heat treatment, where there are some oxygen vacancies, and when these oxygen vacancies are filled with oxygen, the overpotential rises rapidly, leading to passivation.

Ruthenium iridium coated anode

New ecological oxygen is generated on the ruthenium-iridium titanium anode during electrolysis, part of which is discharged at the interface between the active coating and the electrolyte and then leaves the anode surface to generate oxygen into the solution; due to the existence of cracks in the active coating, while another part of oxygen is adsorbed on the anode surface and reaches the interface between the coating and the titanium plate substrate by diffusion or migration through the active coating, and then oxygen is chemisorbed on the titanium substrate surface to generate an un conductive oxide film (TiO2), which generates reverse resistance. The increase in potential further promotes the dissolution of the coating and the oxidation of the titanium substrate.

These are some of our conclusions. It is possible for the anode to passivate, and we should do a good job of inspection and maintenance.

DINOR MMO anode has excellent antimicrobial corrosion performance, long electrode life and high current efficiency. mmo oxide is a rather stable oxide and the anode coating is a ceramic oxide of precious metal iridium, which is almost insoluble in any acid or base. MMO anode does not contaminate the plating solution, and the same is true for platinum plated electrodes.

Please visit our website to see our product range and send us a message to get a quote.