Home / News / Different Applications of Titanium Anodes in Electroplating Process

Mar. 29, 2022

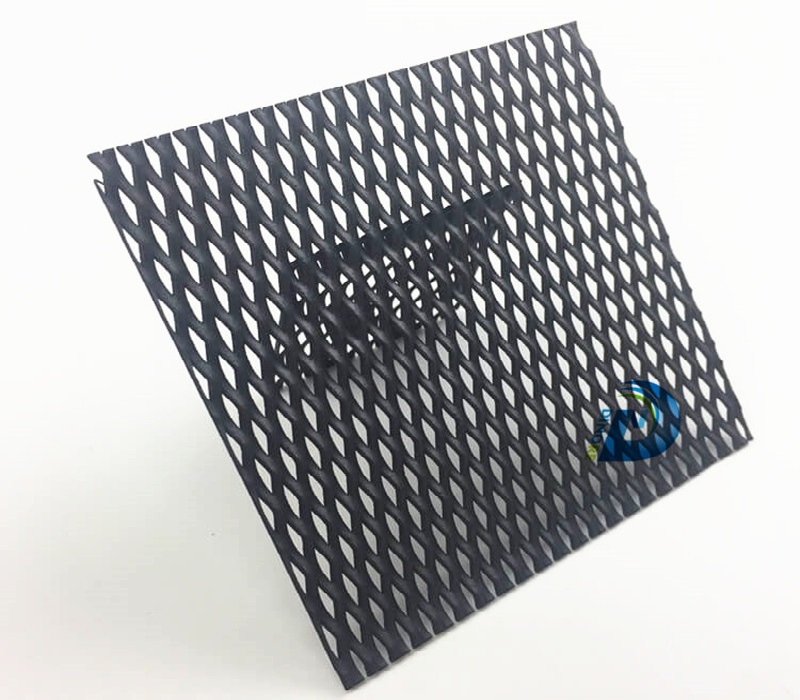

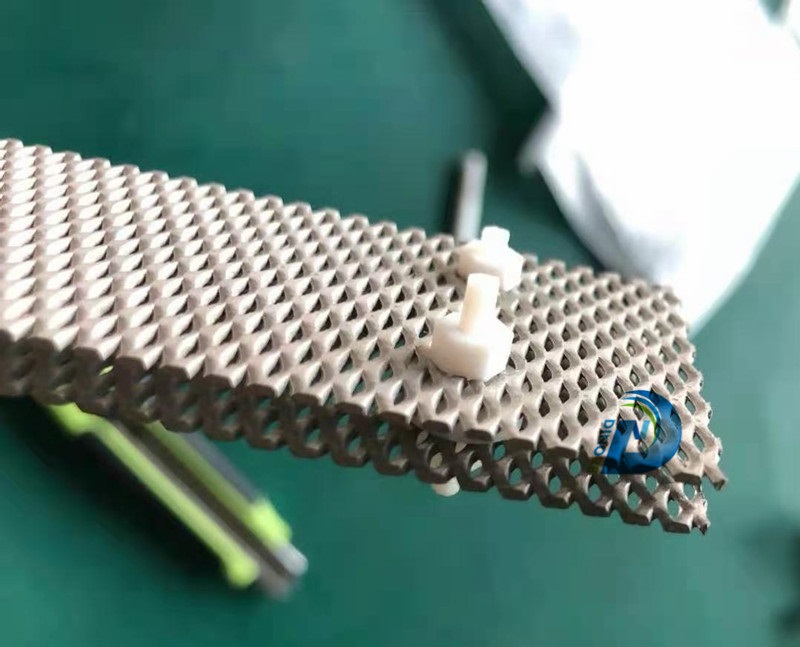

Titanium anode is one of the DSA anode, it is coated with mixed metal oxide coatings such as ruthenium iridium, iridium tantalum on the titanium substrate. MMO coated titanium anodes were originally developed for chlorine production by seawater electrolysis and have been used in cathodic protection (CP) applications since the 1980s. Dinor can design and customize various sizes of the coated titanium anodes. We offer our customers MMO tube anodes and other titanium anodes, among others.

There are two main systems used in the production of trivalent chromium chromium plating: the chloride system and the sulfate system. Both systems have their own characteristics, the chloride system has good electrical conductivity of the solution, white coating, the use of graphite as anode, and lower slotting costs. However, compared with the sulfate system, the following defects are apparent.

1) The chloride system produces chlorine gas which is harmful to human body and causes secondary pollution during the plating production process.

2) the use of graphite as anode, due to the high oxygen precipitation overpotential of graphite, easy to produce hexavalent chromium, which not only affects the stability of the plating solution, but also has a strict limit on the concentration of the presence of this harmful substance in the plating solution.

3) Graphite is deformed by long-term use due to corrosion of the anode, and the area of the anode changes, resulting in instability of the process and contamination of the plating solution by slag.

4) chloride has a strong corrosive effect on plating equipment.

5) Special system is needed to purify the plating solution and the maintenance cost is high.

Therefore, more and more trivalent chromium chromium plating process using sulfate system, and the use of insoluble precious metal coated titanium anode as the anode, it is basically insoluble in the plating process, therefore, also known as "size stable anode".

Titanium seamless tube/Titanium pipe

Electro-galvanized sheet has good corrosion resistance, processability, weldability, and paintability, and is mainly used in the automotive, home appliance, and light industrial sectors. Electro-galvanized products are available in double-sided, single-sided, and differentially thick plating, depending on the plating layer. Also, according to the post-plating treatment, there are passivation, phosphating, and fingerprint resistance products.

Tin-plated sheet is mainly used in the packaging industry and has excellent corrosion resistance, good appearance, high strength, light weight, good formability, and good resistance to organic substances, dilute acids, alkalis and salts. Tin-plated sheet products can be further subdivided into two categories: food (also known as food packaging products) and general purpose products (i.e., non-food packaging products).

After several pretreatment processes, the cathodized strip passes through a series of electrolytic cells. The electrolyte in these cells contains dissolvable zinc or tin ions, which are electrochemically deposited on the surface of the strip after an electrochemical reaction.

Electrodialysis is a physicochemical process in which ions migrate from one part of water to another part of water under the action of an applied DC electric field, using the selective permeability of ion exchange membranes. Electrodialysis desalinator is the use of electrodialysis process in multi-layer compartment to achieve the purpose of water desalination. The main applications of electrodialysis in wastewater treatment engineering are desalination of wastewater, and recovery and utilization of useful substances. In some biochemical wastewater, the COD and salt content are very high. When treating these wastewaters by biochemical method, the high concentration of salt makes it impossible for bacteria to grow, so electrodialysis can be used to desalinate these wastewaters and reduce the salt content before biochemical treatment. Inorganic salts that can be recovered in paper and electroplating wastewater can be recycled by electrodialysis.

Continuous electrodeionization (EDI) to produce ultra-pure water

Electrodialysis reactor (ED/EDR) for material separation

Separation and high salt wastewater concentration

Desalination of seawater and brackish water

Our precious metal oxide ruthenium-iridium coated titanium anodes are available in plate, tube and mesh form or can be customized. You can visit our website to find the right product and contact us to get a quote.