Home / News / Lengthen the Service Life of MMO Auxiliary Anode

Jun. 28, 2022

The auxiliary anode has gone through the development stages of iron and steel anode, graphite anode, high silicon cast iron anode and metal oxide coating anode. with the application of new materials and new technology, the auxiliary anode has improved obviously from current efficiency to service life. Due to the use of titanium as the substrate and platinum group metal oxides with high catalytic activity as the coating, the metal oxide coating anode has good conductivity and low surface output resistance, and it is not eroded by the medium. and easy to process and other advantages.

Because the MMO precious metal oxide auxiliary anode has the advantages of small size, large current, micro-solubility and light weight, this type of anode is often used in pipeline inner wall applied current cathodic protection, and the actual application effect is ideal.

However, with the passage of time, the precious metal oxide coating on the anode surface may be lost, because the oxide coating consumes to expose the substrate, and the titanium dioxide passive film is formed on the titanium substrate surface under the influence of cathodic protection system. The formation of passivation film can effectively restrain the corrosion of the substrate, but the electrical conductivity also decreases.

The loss of oxide coating is caused by the following factors:

The adhesion of oxide coating is poor, and the loss of oxide coating is affected by water erosion.

Large output current of auxiliary anode, resulting in coating consumption.

Wear and scratches caused by outer packaging, handling and installation.

Ruthenium iridium coated anode

Titanium is a very active metal with low equilibrium potential and high thermodynamic corrosion tendency in the medium. But in fact, titanium is very stable in many media, such as titanium is corrosion resistant in oxidizing, neutral and weak reducing media. This is because titanium and oxygen have a great affinity, and a dense, strong adhesion and inert oxide film is formed on the surface of titanium in air or in oxygen-containing medium, which protects the titanium matrix from corrosion. even due to mechanical wear, it can quickly heal or regenerate.

Titanium dioxide, the main oxide of auxiliary anode substrate, generally does not conduct electricity in non-UV environment, and the layering of oxide is titanium dioxide (white) on the surface, titanium monoxide and titanium trioxide on the bottom. Thus it can be seen that the wear and tear of the auxiliary anodized layer exposed the substrate is non-conductive.

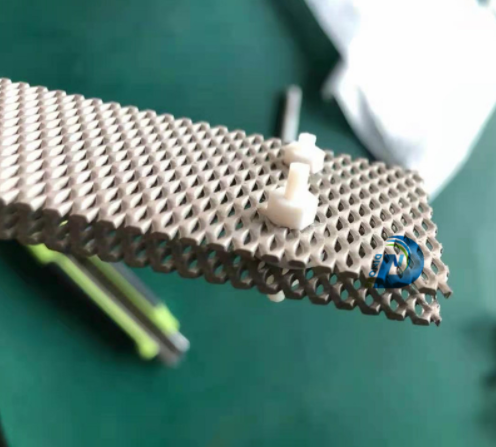

Platinized Titanium Mesh Anode

Attention should be paid to the adhesion of precious metal oxide coatings. At the same time, the transportation process should be handled gently and there should be protective covers.

For the MMO precious metal oxide auxiliary anode used in flowing seawater, attention should be paid to the wear problem of the auxiliary anode oxide coating on the water front, which can be solved by properly setting the position, increasing the thickness of the oxide coating and changing the shape of the auxiliary anode in the design process.

The wear of the anode body should be fully considered in the installation process of the MMO auxiliary anode used in the soil, and the pre-package type can be adopted, such as defining the coke particle size, setting the anode locator, proper water injection in the well and so on to reduce the damage to the oxide layer of the anode body.

Because the design life of cathodic protection is generally long and the cost of maintenance and replacement of auxiliary anodes is high, the accurate test and estimation of the service life of MMO precious metal oxide anodes can ensure the service life of anodes while saving costs, which is of practical significance.

For more info and the quote, please contact DINORE, we welcome your inquiries.